Automated platforms for scaling up nanomaterials self-assembly

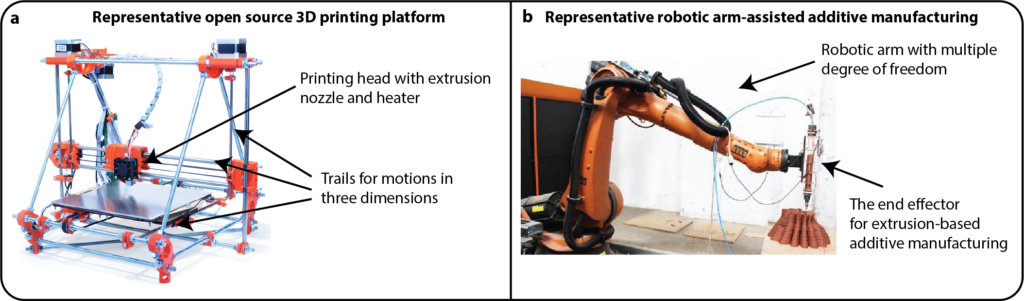

Two examples of automation platforms are (a) a three-dimensional (3D) printer (image credit: reprappro.com) and (b) a robotic arm (image credit: Institute for Computational Design, University of Stuttgart).

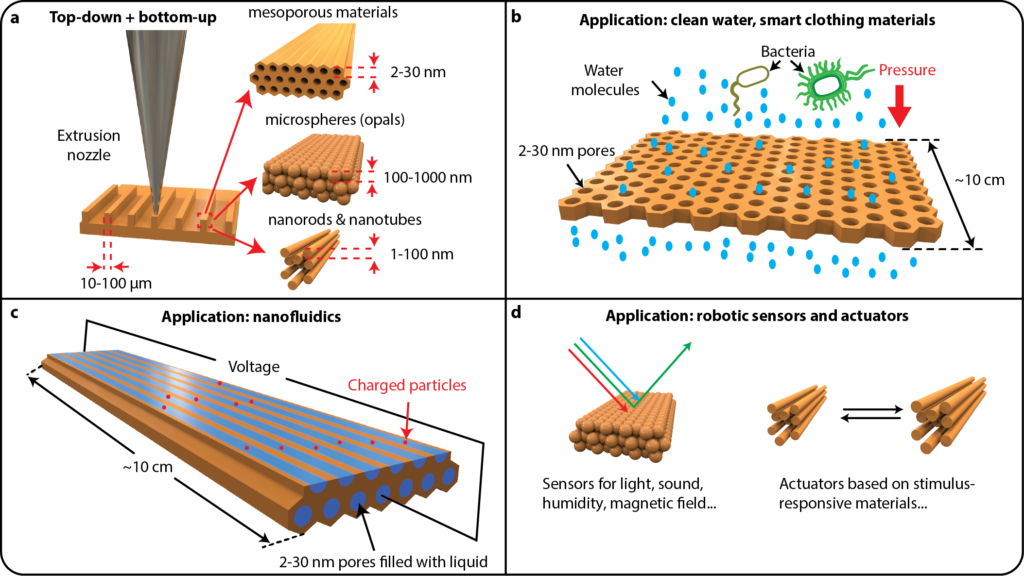

Automation of nanomaterials self-assembly and potential applications. (a) Schematics of extrusion-based additive manufacturing of representative nanomaterials, such as mesoporous materials, colloidal spheres, nanorods, and nanotubes. (b) A centimeter-scale sheet of mesoporous materials with vertically-aligned pores for water purification or smart clothing. (c) Horizontally-aligned mesopores serving as channels for nanofluidics. (d) Synthetic opals as sensors; fibers of aligned nanorods and nanotubes as actuators for robotic applications.

Selected relevant publications:

- Giochini. P.A. †; Gupta, S.S. †; Wang, W.; Wood, D.; Yunusa, M.; Baharlou, E.; Sitti, M.; Menges, A., Additive manufacturing of cellulose-based materials with continuous, multidirectional stiffness gradients. Sci. Adv. 6, eaay0929 (2020). Publisher’s version, PDF

- Wang, W., Lofgreen, J. E. & Ozin, G. A. Why PMO? Towards functionality and utility of periodic mesoporous organosilicas. Small 6, 2634-2642 (2010). Publisher’s version, font cover

- Wang, W., Grozea, D., Kohli, S., Perovic, D. D. & Ozin, G. A. Water repellent periodic mesoporous organosilicas. ACS Nano 5, 1267-1275 (2011). Publisher’s version